All projects

Various projects are presented here

Video about modified houses Virmak

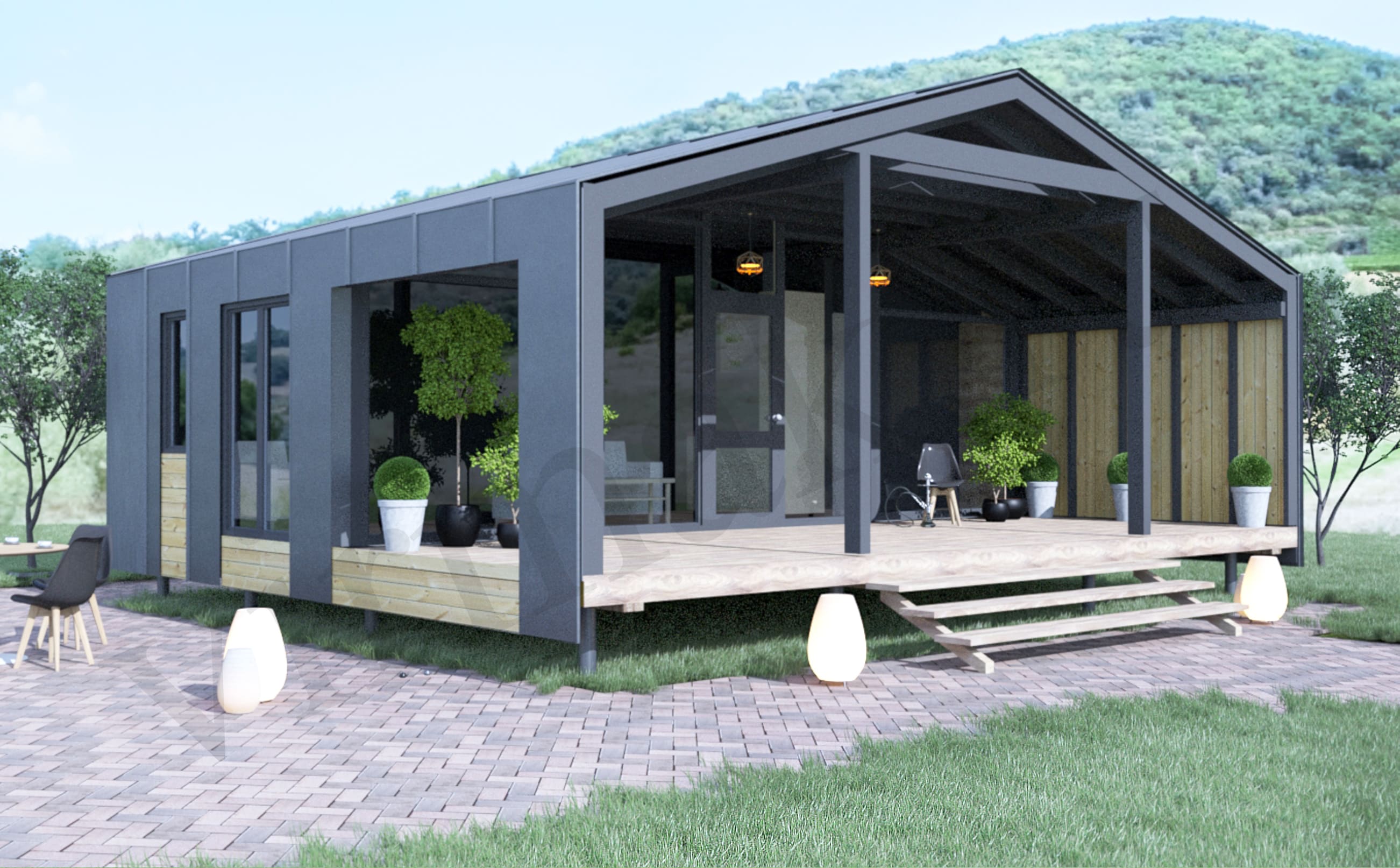

Choosing a ready-made house project from SIP panels is the optimal solution that allows you to quickly get a modern, energy-efficient and cheap turnkey housing.

The technology is a type of frame construction, which involves the use of ready-made elements manufactured in the factory during the Assembly of cottages. Walls, roofs and ceilings are made of structured SIP panels, and pile-screw or tape bases are used as the Foundation, so the cost of the structure is very affordable. Buildings are light, so they can be built on almost any type of soil.

Instruction

Frame floor of SIP home

House with your own hands

using SIP technology

×